Wood Gets a Makeover: How Scientists are Creating See-Through Lumber

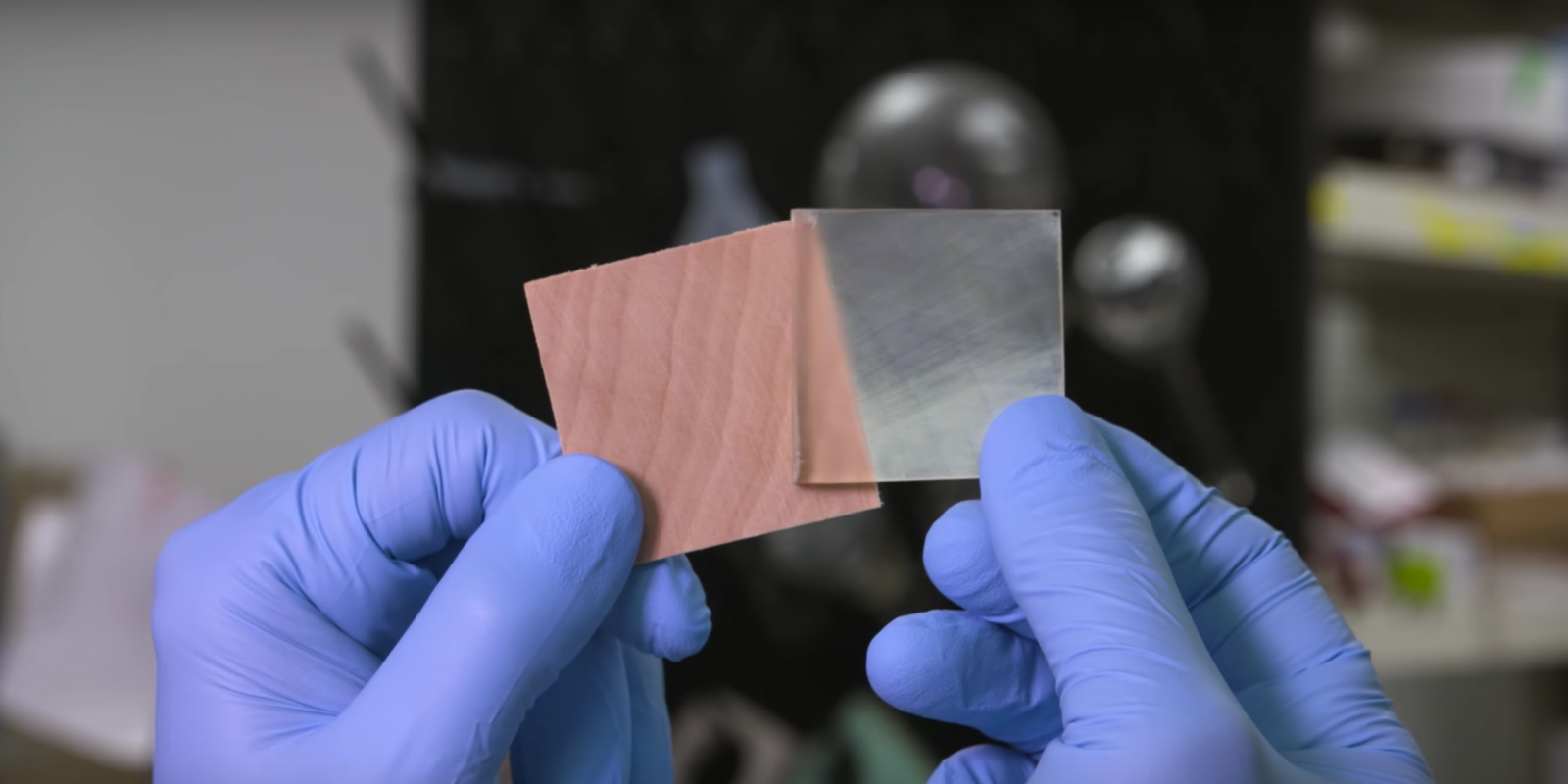

Transparent wood is a fascinating material that holds promise for a wide range of applications, from sustainable construction to advanced optics. The process of making transparent wood involves impregnating wood with chemicals to remove lignin, which is the component responsible for the wood's opacity. One significant research article on this topic is "Optically Transparent Wood from a Nanoporous Cellulosic Template: Combining Functional and Structural Performance" by Berglund et al. (2016), which provides valuable insights into the chemical process behind transparent wood production.

To start, wood is primarily composed of cellulose, hemicellulose, and lignin. Of these components, lignin is what gives wood its characteristic brown color and makes it opaque. The goal of making transparent wood is to selectively remove lignin while preserving the wood's structural integrity. This process involves several key steps.

Firstly, the wood is typically cut into thin sections or veneers to facilitate the chemical treatment. These sections are then immersed in a solution containing a lignin-removing chemical, such as hydrogen peroxide (H2O2) or sodium chlorite (NaClO2). These chemicals work by breaking down the lignin molecules, making them soluble and easier to remove from the wood fibers.

The immersion process is often combined with heating or vacuum techniques to enhance the penetration of the chemicals into the wood structure. This ensures a more uniform removal of lignin throughout the wood, leading to a consistent level of transparency.

After the lignin removal stage, the wood undergoes a series of washing and drying steps to remove residual chemicals and moisture. This is crucial for achieving the desired optical clarity in the final product. The treated wood is then compressed to increase its density and improve its mechanical properties.

Berglund et al. (2016) describe a specific method for creating transparent wood using a nanoporous template approach. In this method, the wood is impregnated with a transparent polymer, such as a monomer mixture containing methyl methacrylate (MMA) and benzoyl peroxide (BPO). The polymer fills the voids left by the removed lignin, creating a transparent matrix within the wood structure.

The nanoporous template method offers advantages such as improved optical properties, mechanical strength, and moisture resistance compared to traditional methods. The resulting transparent wood exhibits high transparency, low haze, and excellent light transmission, making it suitable for applications in windows, solar panels, and light-guiding devices.

In conclusion, the production of transparent wood involves a complex chemical process aimed at selectively removing lignin while preserving the wood's structure and properties. Research articles like Berglund et al. (2016) provide valuable insights and innovative techniques for advancing the development of transparent wood as a sustainable and versatile material.

Similar Post You May Like

-

CFCs, HFCs and their long, troubled history

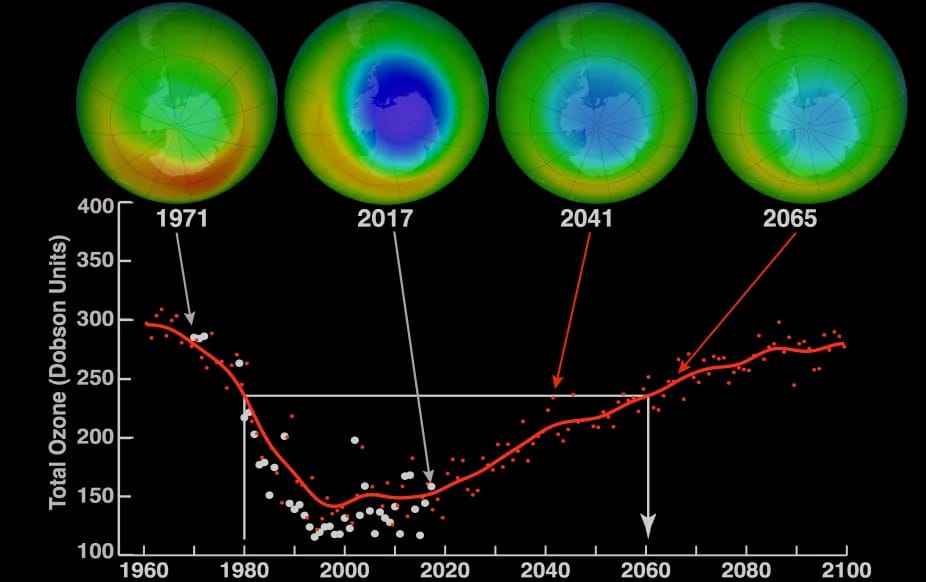

At its peak, the ozone hole covered an area 7 times larger than the size of Europe, around 29.9 million km2, and was rapidly expanding

-

The Origin of Universe: Deciding point where it all began!

Let us unravel and surf through the ideas throughout ages to understand what the universe and its origin itself was to its inhabitants across history.

-

The Artemis Program

Inspired by the Greek goddess of the Moon, twin sister to Apollo, the artimis program was named on 14 May 2019 by Jim Bridenstine.